Instapak® SpeedyPacker Insight ®

Ensure quick, cost-effective product protection with the Instapak® SpeedyPacker foam-in-bag system

Reduce Damage Rates

Create custom Instapak® foam-in-bag cushions that help reduce damage while optimizing pack size and material usage

Save Bag Size & Fill Settings

Simplify production by programming the bag size and foam fill combinations that your team regularly uses

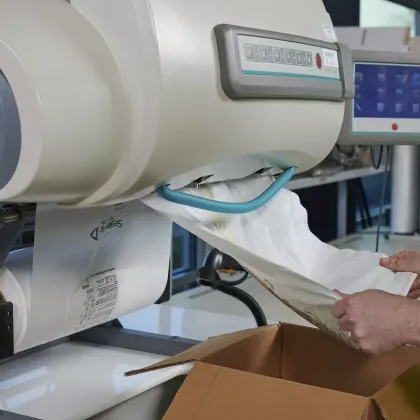

The SEALED AIR® brand Instapak® SpeedyPacker® system delivers expanding packing foam to high-volume packaging operations for quick, cost-effective product protection. A versatile industrial-grade touch screen display lets the operator select the optimum bag size and foam combinations for fast, secure protection for a wide variety of items. Each custom-shaped cushion absorbs bumps and bruises during the shipping process.

- Cost-effective, superior product protection

- Expanding packing foam cushions for a custom fit

- Easy to use industrial-grade touch screen display

- Select optimum bag size and foam combinations

- Nearly limitless cushion combination options available, including Continuous Foam Tubes (CFTs)

- Programmable; create sequences of bags and/or CFTs with the push of a button

Machine Size:

Benchtop: 52 in W × 30 in D × 47 in H (132 cm x 76 cm x 119 cm)

Floor model: 52 in W × 38 in D × 79 in-103 in H (132 cm x 97 cm x 201 cm-262 cm)

Film Size:

12 in and 19 in W available

Production Rate:

21 12-in bags per minute, 50% foam-filled

Electrical:

200-240 VAC, Single-Phase 30 Amp

Receptacle Type:

NEMA L6-30R, UL and CE Approved